Plate Heat Exchanger (PHE) is a compact, efficient heat transfer device designed for heating, cooling, or heat recovery between two fluids. Comprising a series of corrugated metal plates stacked together, it creates multiple flow channels that maximize surface area and turbulence, resulting in exceptional heat transfer efficiency. Ideal for applications requiring precise temperature control, energy savings, and space optimization, PHEs are widely used in HVAC, industrial processes, and renewable energy systems.

Due to the special effect of the plate corrugated surface, the plate heat exchanger makes the fluid flow along the corrugated channel, and the direction of its velocity changes continuously, causing the fluid to arouse a strong end motion at a small flow rate, thus strengthening the transmission. heat process. The heat transfer capacity is effectively improved, and it has the outstanding advantages of compact structure, low metal consumption, high operational flexibility, and long service life.

The process of the heat exchanger is assembled by many plates according to certain process and technical requirements of the buyer. When assembling, the plates A and B are arranged alternately, and a mesh is formed between the plates. The gasket seals the hot and cold media in the heat exchanger, and at the same time reasonably separates the hot and cold media without mixing them. The hot and cold fluids in the channel Interval flow can be countercurrent or downstream as required. During the flow, the hot and cold fluids exchange heat through the plate surface to achieve the desired effect.

There are many process combinations of plate heat exchangers, all of which are realized by using different reversing plates and different assemblies. Process combination forms can be divided into single process, multi-process and mixed process forms.

High Efficiency: Heat transfer coefficients higher than shell-and-tube

Compact Size: 50-80% smaller footprint than equivalent shell-and-tube units

Easy Maintenance: Plate pack can be opened for inspection and cleaning

Flexibility: Capacity easily increased by adding plates

Low Fouling: High turbulence reduces scaling and deposits

Plate heat exchangers are used in food and beverage processing:

All kinds of dairy products: fresh milk, milk powder, milk drinks, yogurt, etc.;

Vegetable protein drinks: peanut milk, milk tea, soy milk, soy milk drinks, etc.;

Juice drinks: fresh fruit juice, fruit tea, etc.;

Herbal tea drinks: tea drinks, reed root drinks, fruit and vegetable drinks, etc.;

Condiments: soy sauce, rice vinegar, tomato juice, sweet and spicy sauce, etc.;

Brewing products: beer, rice wine, rice wine, wine, etc.

Plate heat exchangers are used in other industrial liquid treatment. On: pharmaceutical, printing and dyeing, HVAC heat exchange, chemical industry, power station, swimming bath heating, petroleum, metallurgy, domestic hot water, shipbuilding, machinery, papermaking, textile, geothermal utilization, Environmental protection, refrigeration.

Energy Savings: 90%+ heat recovery efficiency reduces operating costs

Proven Reliability: 20+ years of engineering experience

Technical Support: Custom engineering for specific applications

Lifecycle Value: Low maintenance and long service life

Sustainability: Reduced carbon footprint through energy efficiency

Cost Effective: Lower initial and operating costs than alternatives

Quick Delivery: Standard units shipped within 45 days

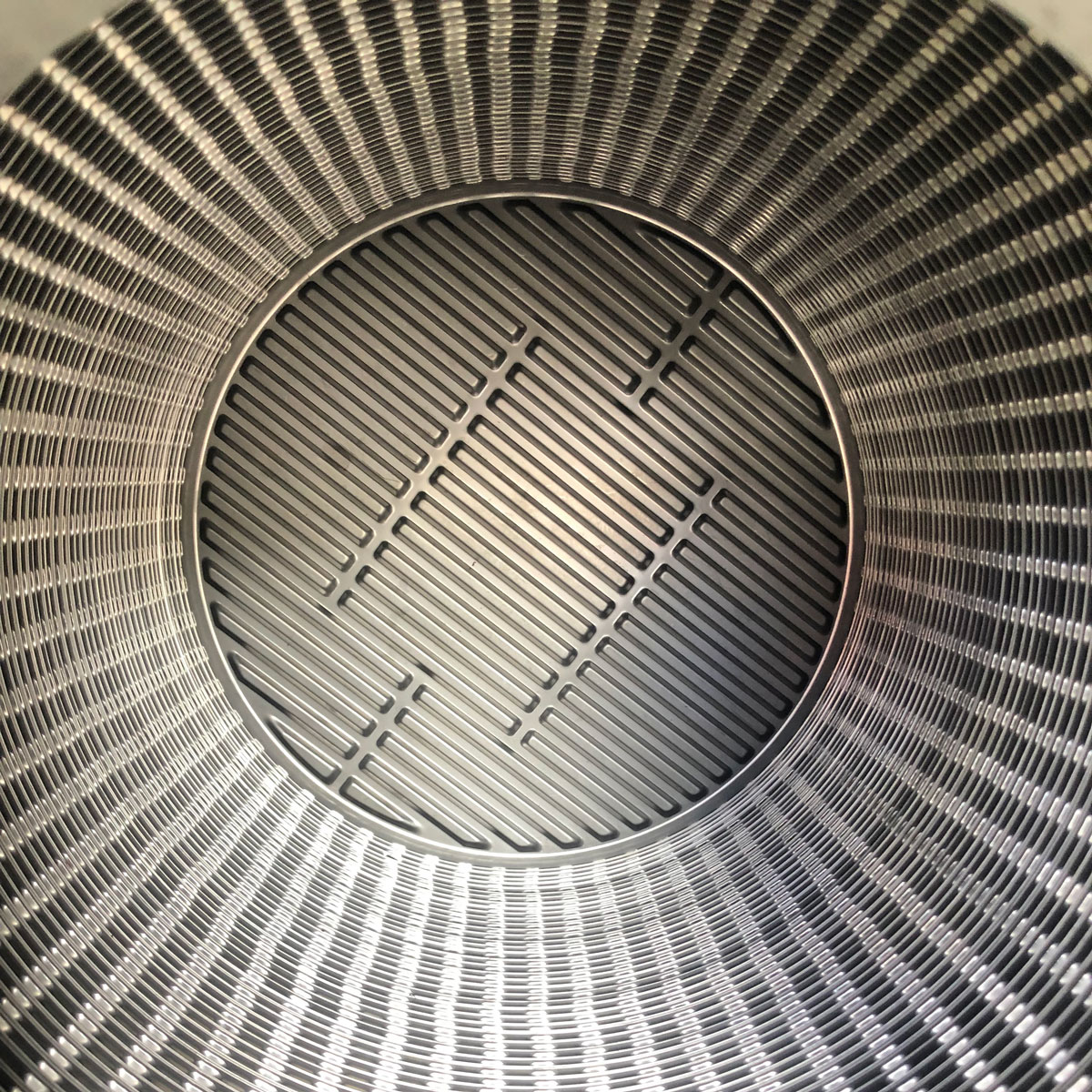

The plate heat exchanger consists of a frame (fixed and movable end plates, tightening bolts) and plate pack (corrugated plates with gaskets or laser-welded seams). Plates are typically made of stainless steel (SS304/SS316L) or other alloys, with patterns optimized for specific duties. Fluids flow alternately between plates, transferring heat through thin metal walls. Designs include gasketed, brazed, and welded types.

Sitemap

Extraction Equipment Suppliers, vacuum concentration tank manufacturers, Emulsifying Mixing Tank, China Jacketed Kettle, jacketed kettle manufacturers, Herbal Extraction Equipment.