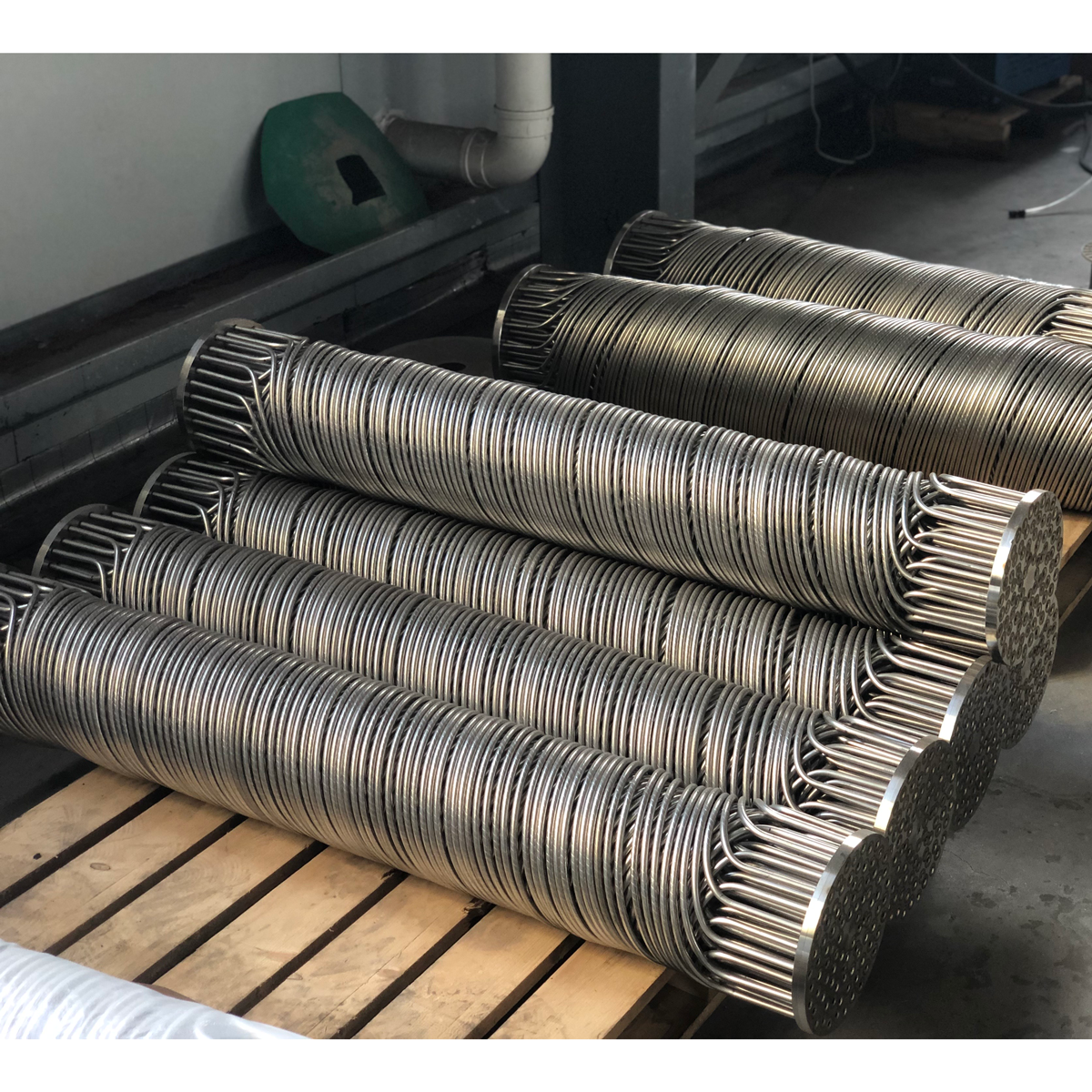

Spiral Wound Heat Exchanger is a high-performance, compact heat transfer device designed for extreme temperature and pressure conditions. Featuring a unique spiral wound tube bundle configuration, it delivers exceptional thermal efficiency and reliability in demanding applications such as LNG processing, hydrogen production, and high-pressure chemical processes. Its robust construction and innovative design make it ideal for services where conventional shell-and-tube exchangers are inadequate.

Multi-Layer Winding: Precision winding technology for optimal flow distribution

Thermal Stress Management: Advanced modeling to minimize differential expansion issues

Leak-Before-Break Design: Multiple safety layers and leak detection systems

Extreme Pressure Capability

Wide Temperature Range

Compact Design: smaller than equivalent shell-and-tube units

High Efficiency: Counter-current flow provides optimal temperature approaches

Multi-Stream Capability: separate fluid streams in one unit

Material Versatility: Alloys suitable for corrosive and high-temperature services

Low Maintenance: Robust construction with long service intervals

Safety Focused: Multiple redundant safety features and leak detection

LNG Processing: Main cryogenic heat exchangers, cold boxes

Petrochemical: High-pressure synthesis, methanol production

Aerospace: Cryogenic fuel systems, environmental control

Chemical Processing: High-pressure reactors, catalyst bed cooling

Energy Storage

Proven Performance: 20+ years of experience in extreme applications

Technical Leadership: Patented winding and manufacturing technologies

Energy Efficiency: better heat transfer than conventional designs

Lifecycle Value: Lower total cost of ownership despite higher initial investment

Custom Solutions: Tailored designs for specific process requirements

This exchanger consists of multiple layers of tubes wound spirally around a central core, housed within a high-pressure shell. The tubes are typically arranged in multiple layers with alternating spiral directions to optimize flow distribution and minimize thermal stress.

Winding tube heat exchanger, L-shaped spiral wound tube heat exchanger, Y-shaped spiral wound tube heat exchanger, Spiral wound tube cooling belt separator, double tube plate spiral wound tube heat exchanger, detachable spiral wound tube heat exchanger.

In order to meet the diversified needs of users for spiral wound tube heat exchangers, through years of accumulation in the field of spiral wound tube heat exchangers, a series of heat exchangers that meet various processes have been developed.

Sitemap

Extraction Equipment Suppliers, vacuum concentration tank manufacturers, Emulsifying Mixing Tank, China Jacketed Kettle, jacketed kettle manufacturers, Herbal Extraction Equipment.