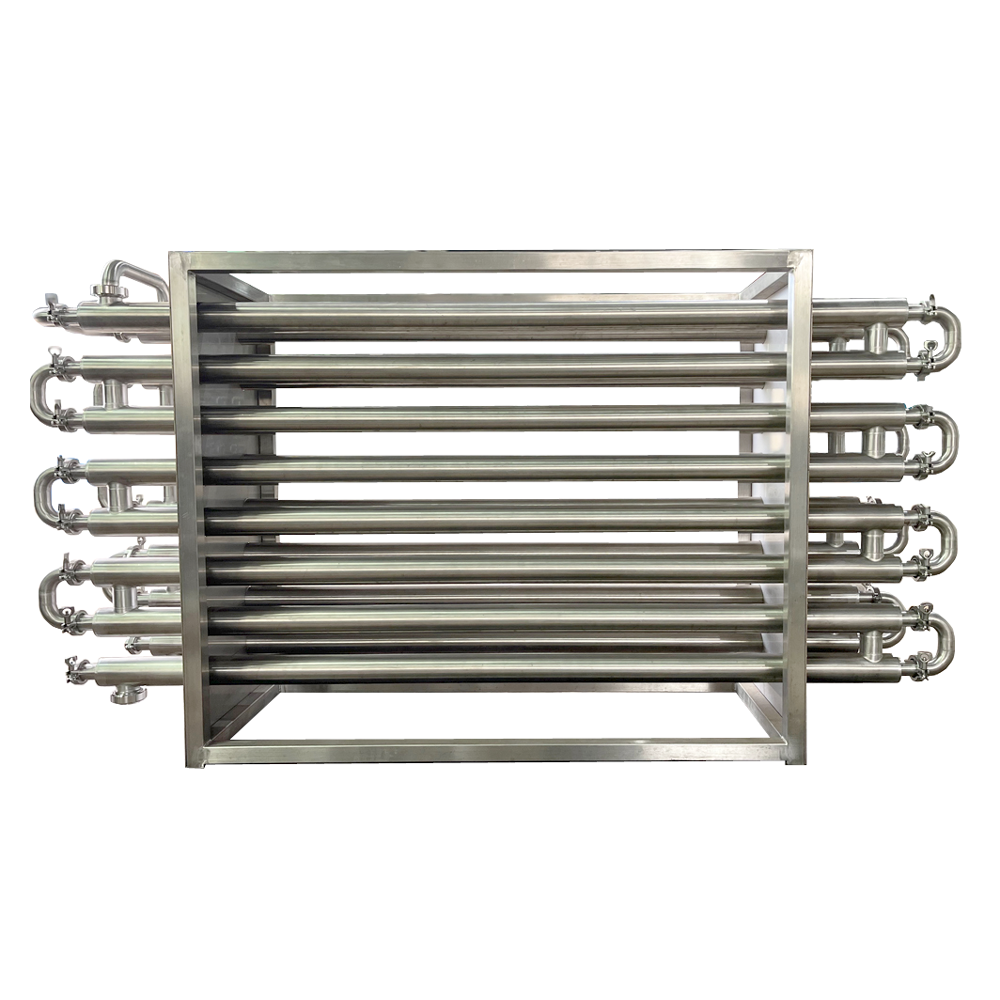

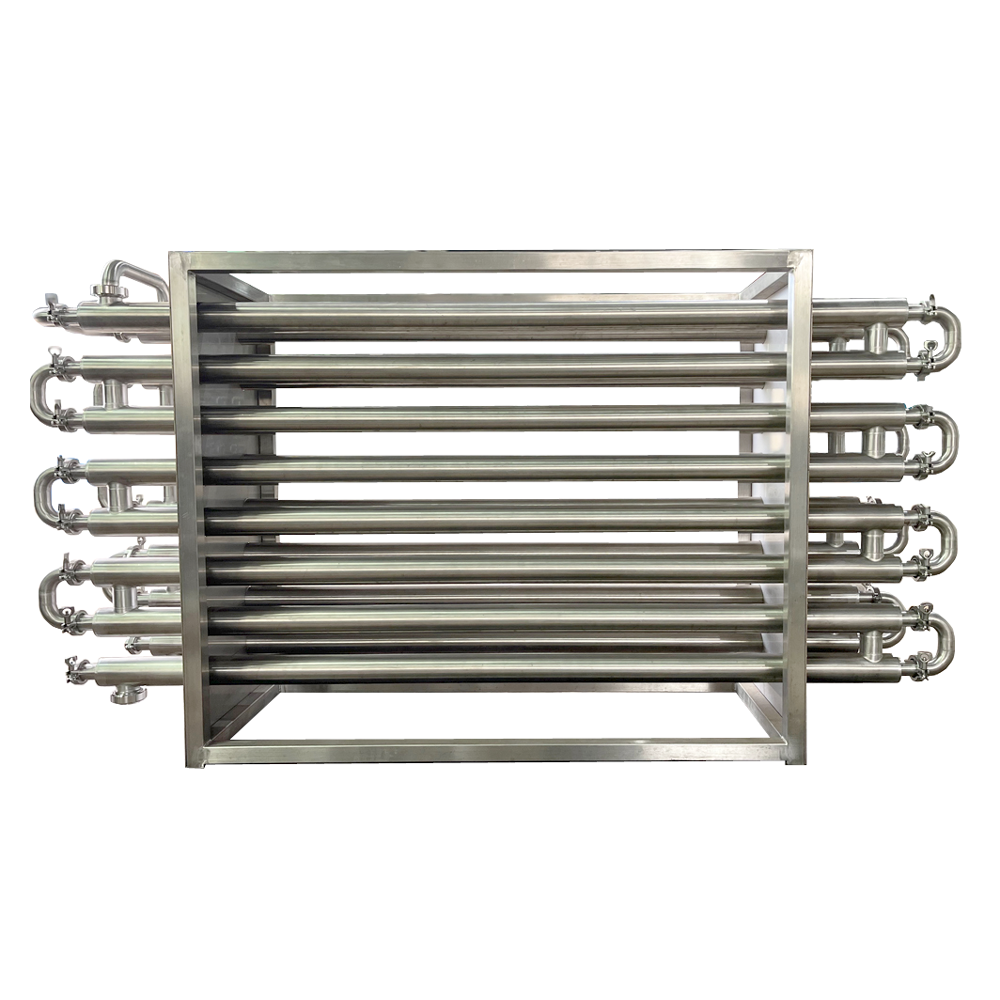

Tube-in-tube (Double-Pipe) Heat Exchanger, also known as a Hairpin Heat Exchanger, is a simple yet efficient heat transfer device consisting of one pipe concentrically mounted inside another. The inner pipe carries one fluid, while the annular space between the pipes carries the other fluid, enabling heat exchange through the inner pipe wall. This design is ideal for applications requiring high pressures, high temperatures, or handling of fouling fluids where simplicity, reliability, and ease of maintenance are critical.

Enhanced Surface Designs: Low-finned inner tubes to increase heat transfer area

Counter-Flow Optimization: True counter-current flow for maximum temperature approach

Modular Construction: Standardized components for easy expansion or reconfiguration

Thermal Stress Management: Expansion joints and flexible designs to handle differential expansion

Temperature Resistance

Fouling Resistance: Easy mechanical cleaning and inspection

Compact Design: Modular arrangement saves space

Material Versatility: stainless steel 304/316L

Low Maintenance: Simple design with minimal components

Leak Containment: Double containment design for hazardous fluids

Energy Efficient: True counter-flow for optimal heat recovery

Oil & Gas: Wellhead cooling, gas compression cooling, amine heat exchange

Chemical Processing: High-pressure reactor feed/effluent exchange

Power Generation: Lube oil cooling, seal oil systems

HVAC: Heat recovery systems, district heating

Industrial Machinery: Hydraulic oil cooling, compressor cooling

Pharmaceutical: High-purity fluid heating/cooling

Proven Reliability: Simple design with decades of proven performance

Extreme Condition Capability: Handles pressures and temperatures beyond most exchangers

Maintenance Friendly: Easy inspection and cleaning without special tools

Customizable: materials and wide range of configurations available

Cost Effective: Lower initial cost for high-pressure/small duty applications

The double-pipe exchanger comprises inner pipes (typically seamless) and outer pipes (shells) assembled in a modular hairpin configuration. With multiple hairpins connected in series or parallel to meet duty requirements. Designs include bare pipe, finned tube (for enhanced heat transfer), and multi-tube variants (multiple inner tubes within one shell). Connections are flanged or welded for integrity under extreme conditions.

Sitemap

Extraction Equipment Suppliers, vacuum concentration tank manufacturers, Emulsifying Mixing Tank, China Jacketed Kettle, jacketed kettle manufacturers, Herbal Extraction Equipment.