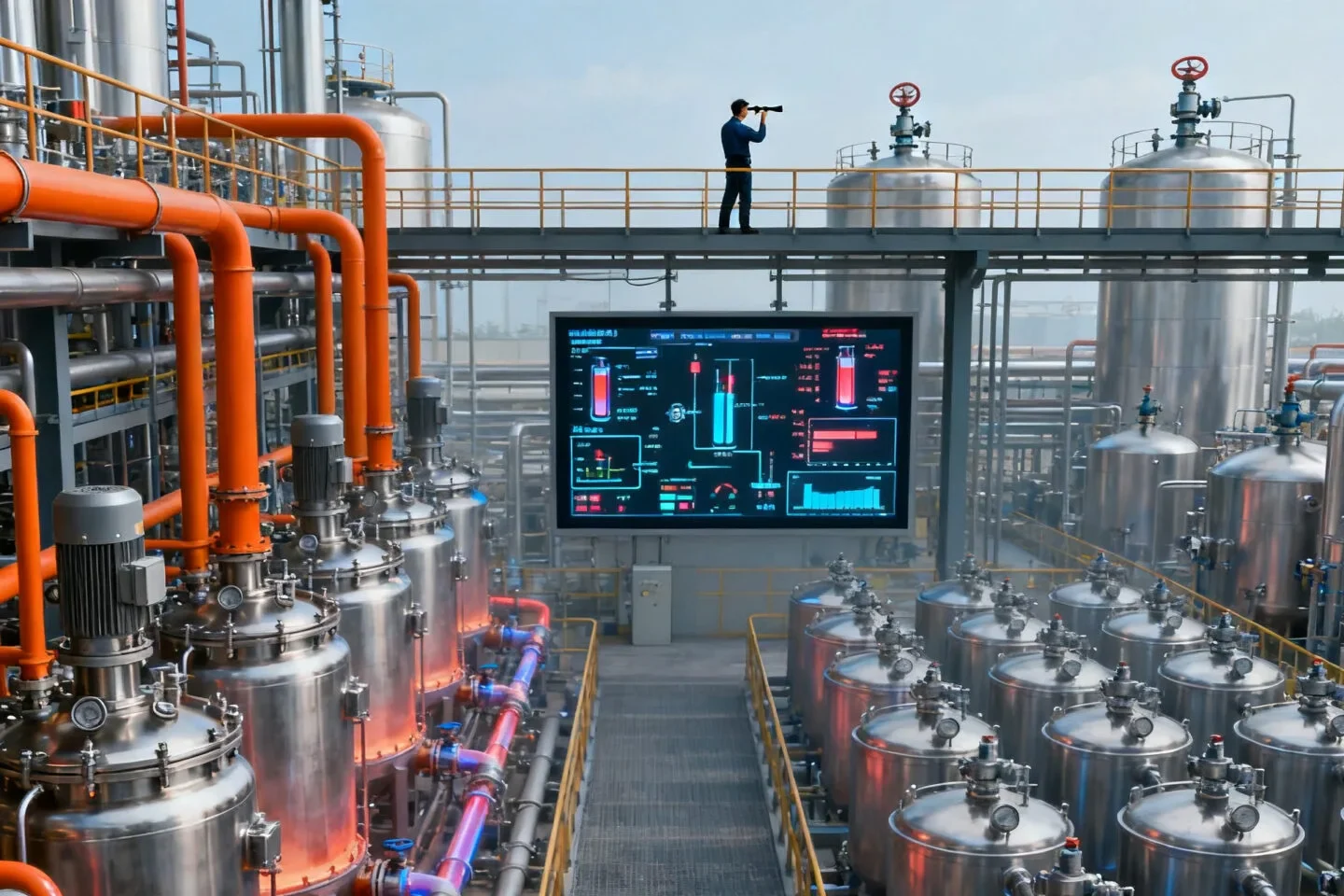

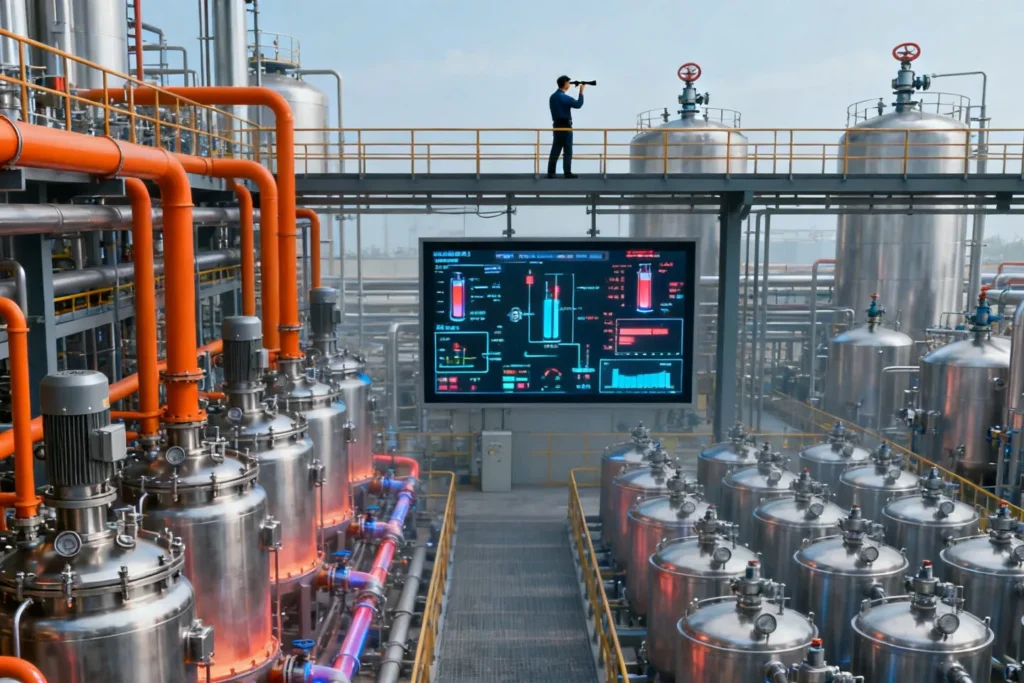

Chemical Industry

Supergravity System: Organic solvent recovery and product separation & purification. Through the supergravity environment, it greatly enhances process efficiency, miniaturizes equipment volume, and significantly reduces investment and operation costs.

Extractor: It provides liquid-liquid extraction towers and solid-liquid leaching systems for the separation and purification of high-value components from complex mixtures (such as flavor extraction, chemical intermediate separation).

Evaporation Concentrator: MVR/ multi-effect evaporation system, used for acid and alkali concentration, process water recovery and pre-treatment of high-salt wastewater, achieving efficient energy utilization.

Stainless Steel Containers: Corrosion-resistant reaction vessels, crystallizers and storage tanks, are core equipment in chemical production, capable of withstanding high temperatures, high pressures and corrosive media.

Heat Exchanger: Various types of tubular shell/plate heat exchanger, which is used for the heating, cooling and heat recovery of the process fluid.