Products

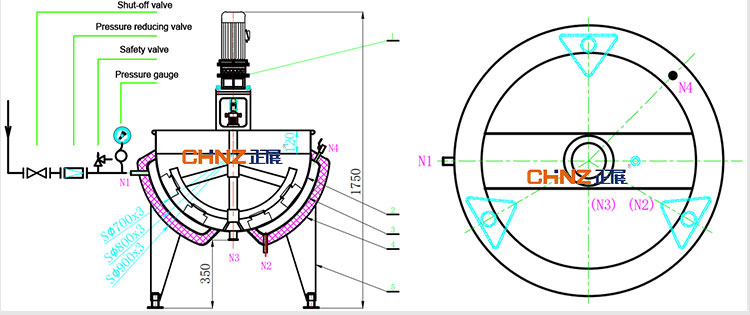

CHINZ Jacketed Kettle Series 30L Industrial Automatic Mixer Equipment Machine With Agitator

Main Feature

The working principle of the jacketed pot is to use back pressure cooking. Simply put, it is to use compressed air to increase the pressure in the pot to prevent the cans from protruding and jumping. Therefore, in the process of sterilization and heating, do not put compressed air, but only need to be in a heat preservation state after reaching the sterilization temperature. After the sterilization is completed, when the temperature is lowered and cooled, the supply of steam is stopped, and the cooling water is pressed into the water spray pipe. As the temperature in the pot drops, the steam condenses, and the pressure in the pot is compensated by the pressure of compressed air. In the sterilization process, attention should be paid to the initial exhaust method, and then the steam is vented to make the steam circulate. It can also be deflated every 15 to 20 minutes to promote heat exchange.