Products

Multi Effect Falling Film Evaporator / Thin Film Evaporator

Product Description

Falling film evaporation is to add the feed liquid from the upper tube box of the heating chamber of the falling film evaporator, and distribute it evenly into each heat exchange tube through the liquid distribution and film forming device. Under the influence of gravity and vacuum induction and air flow, it forms a uniform film. Flow up and down. During the flow process, it is heated and vaporized by the shell-side heating medium, and the generated steam and liquid phase enter the separation chamber of the evaporator together. After the vapor and liquid are fully separated, the steam enters the condenser to condense (single-effect operation) or enters the next-effect evaporator as The medium is heated to achieve multi-effect operation, and the liquid phase is discharged from the separation chamber.

Function

Forced circulation type single, double, three-effect and multi-effect

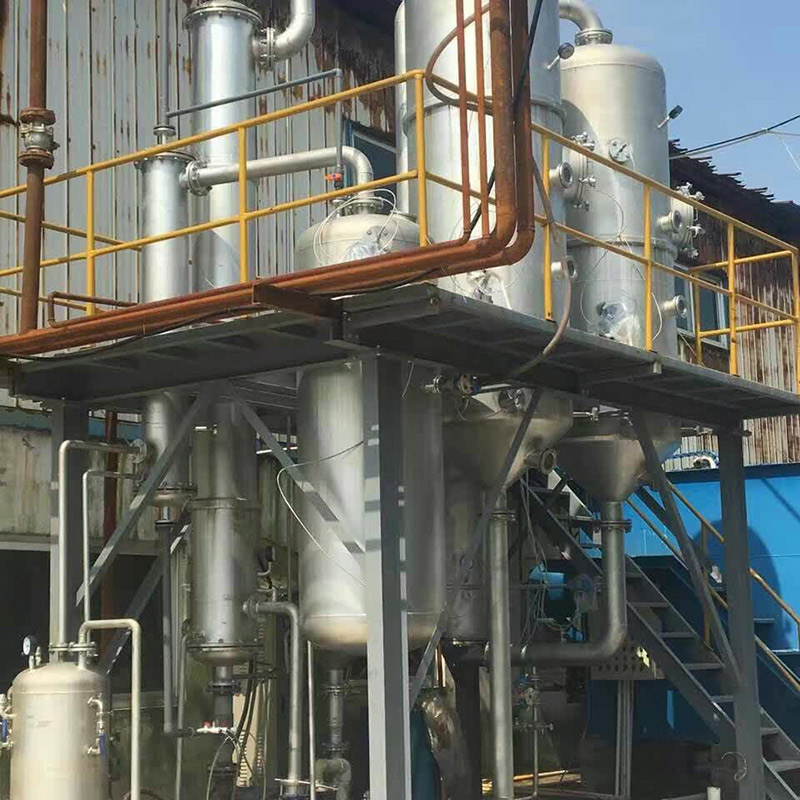

Evaporator is suitable for the low temperature concentration of food, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling and other industries of high concentration, high viscosity, insoluble solids. It assembled by multi-effect heater, multi-effect separator, cooling machine, circular pump, vacuum

and drainage system, steam header, operation platform, Electric PLC controller, valves and cables etc.

Advantage

1. The whole system is reasonable designed, nice appearance, high stability, high energy saving and low steam consumption

2. The concentrate rate is big and time is short, the forced circulation could evaporate the high viscosity material.

3. The special design could achieve the easy operation and able to change the evaporate effect according to different products.

4. The steam temperature is low, the heat will be used fully and the material could be heated evenly. It applies to concentrate the heat-sensitive material.

5. The material could be heated evenly through the forced circulation. The coefficient of the heater transfer in the tubular is high enough to avoid the “Dry wall” issue.

6. The material goes in the separator and be separated again, it enhances the effect of the separation.

7. The evaporator has the advantage of compact designed, small space occupation and straightforward layout, it represents the trend of the development of the big evaporator.

8. It could achieve continuous input and discharge materials. It is also able to control the liquid level and concentration according to your requirement.

9. The evaporated volume could be designed according to your requirement.