Products

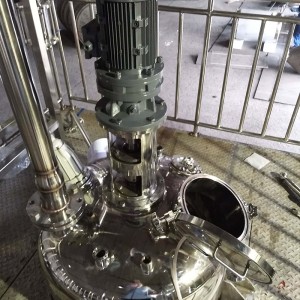

Pharmaceutical Extracting Tank

Extraction And Concentration System

This equipment can be used in various process operations such as normal pressure, water decoction, wet soaking, heat reflux, forced circulation infiltration, aromatic oil extraction and organic solvent recovery in the industries of medicine and health care, pigment, food and beverage, animal and plant, chemical industry and so on.

COMPACT DIMENSIONS

STEAM EFFICIENCY

SAFETY FRAME

SIMPLE CONTROL

EASY MAINTENANCE

VERSATILITY

SOLVENT FOR RECYCLING USE

Herbal

pressurized water decoction, warm immersion, heat reflux, forced circulation, seepage, aromatic oil extraction

Herbal

Extraction – During this process, biomass is placed inside extraction vessel with a solvent(Ethanol, water, and so on.) to remove soluble components, followed by filtration and separation process. The solvent then needs to be recovered from dry biomass

Essential Oil

Essential oils are generally extracted by distillation, often by using steam. Other processes include expression, solvent extraction, sfumatura, absolute oil extraction, resin tapping, wax embedding, and cold pressing.

| Specifications | TQ-Z-1.0 | TQ-Z-2.0 | TQ-Z-3.0 | TQ-Z-6.0 | TQ-Z-8.0 | TQ-Z-10 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Design pressure in the tank | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Design pressure in the jacket | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Design pressure in the jacket | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 |

| Diameter of feeding inlet | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area | 3.0 | 4.7 | 6.0 | 7.5 | 9.5 | 12 |

| Condensing area | 6 | 10 | 12 | 15 | 18 | 20 |

| Cooling area | 1 | 1 | 1.5 | 2 | 2 | 2 |

| Filtering area | 3 | 3 | 3 | 5 | 5 | 6 |

| Diameter of residue discharging door | 800 | 800 | 1000 | 1200 | 1200 | 1200 |

| Energy consumption | 245 | 325 | 345 | 645 | 720 | 850 |

| Equipment weight | 1800 | 2050 | 2400 | 3025 | 4030 | 6500 |