Products

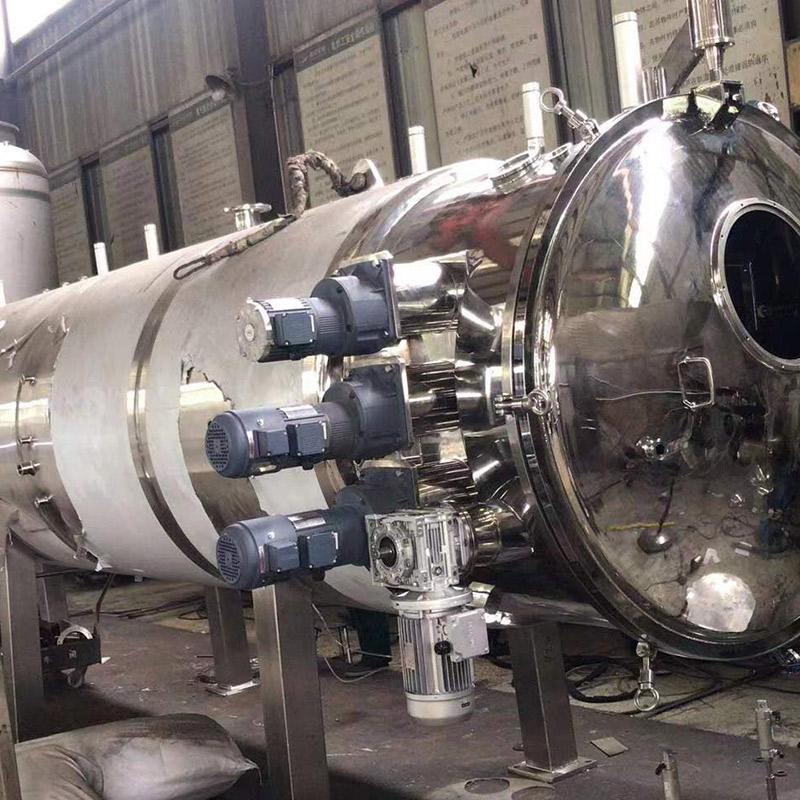

Plant extract powder paste automatic continuous vacuum belt dryer

EQUIPMENT ADVANTAGE

1.Less labor cost and energy consumption

2.Little loss of product and solvent recycling possible

3.PLC automatic control system & CIP cleaning system

4.Good solubility & excellent quality of the products

5.Continuous feed-in, dry, granulate, discharge in vacuum state

6.Completely closed system and no contamination

7.Adjustable drying temperature (30-150℃)& drying time (30-60min)

8.GMP standards

If the solvent of raw material is organic (ethanol, acetone, methanol etc.),evaporation capacity would rise. Evaporation capacity is closely related with drying temperature.

Vacuum belt dryer (VBD) is mainly used in drying many kinds of liquid or paste raw material, such as Traditional & western medicines, food, biological products, chemical material, health foods, food additive etc, especially suitable for drying material with high-viscosity, easy agglomeration, or thermoplastic, thermal sensitivity, or material that can not be dried by traditional dryer.